SEA-LNG is delighted to highlight this article by Reetta Kaila, Technology & Development Manager, Biogas Solutions, Wärtsilä Gas Solutions. The original article can be found here.

Reetta says the journey towards a zero-emissions future in the maritime economy involves using fuels and technology currently available while working to scale other options.

Thanks to a new, ambitious International Maritime Organization (IMO) strategy aimed at reducing greenhouse gas emissions and calls from the European Parliament and European Commission to reduce global emissions from shipping, the maritime industry is waking up to the reality that change is coming.

Shipping is a derived demand and that demand is growing. A growing global population demands more consumables, more transport, and more technology, which in turn drives energy consumption. To steer humanity towards a more sustainable future, we need to find new ways of producing that energy, moving towards circular economy thinking and the use of sustainable fuels.

Helping our customers navigate mounting pressures to combat rising emissions while securing sustainable profitability is of paramount importance to us at Wärtsilä. The challenge lies in the fact that the industry is yet to discover an elixir that will enable a zero-emissions shipping ecosystem. A combination of energy-saving applications, smart propulsion technologies and broader collaboration can nudge us significantly closer to achieving full decarbonisation. But the single biggest intervention is fuel choice.

The path to a zero-emissions future

For the shipping industry, the path to a zero-emissions future is likely to encompass the journey from LNG to bio-LNG and synthetic LNG. While hydrogen, methanol, and ammonia are potentially viable future fuels, for the moment there are obstacles to overcome which will take substantial time to solve, including environmental friendly production and capacity, and supply chain infrastructure. LNG only attained commercial viability after a long period of R&D and testing covering the whole supply chain followed by acceptance by marine classification societies. Bio-LNG and synthetic LNG can leverage the fossil LNG infrastructure since these can be blended in all ratios with fossil LNG as soon as their production rates and economics are in place. “The use of bio-LNG as a drop-in fuel by just 10% may extend compliance by couple of years, which bring long term competitive advantage” as John Hatley SEA-LNG investment committee chairman described in article in SEA-LNG from February this year.

Given this likely progression, the internal combustion engine will remain the best option for upping our climate change mitigation game. It offers the most realistic emissions-reduction potential because there’s nothing it can do with Heavy Fuel Oil (HFO) that cannot be done with Liquefied Natural Gas (LNG) and future fuels. Wärtsilä dual-fuel engines, which entered the market more than three decades ago, are capable of being converted to use almost all liquid and gaseous fuels, including blends of green ammonia, hydrogen and methanol. With the internal combustion engine, the fuel doesn’t matter because the engine is fuel-flexible.

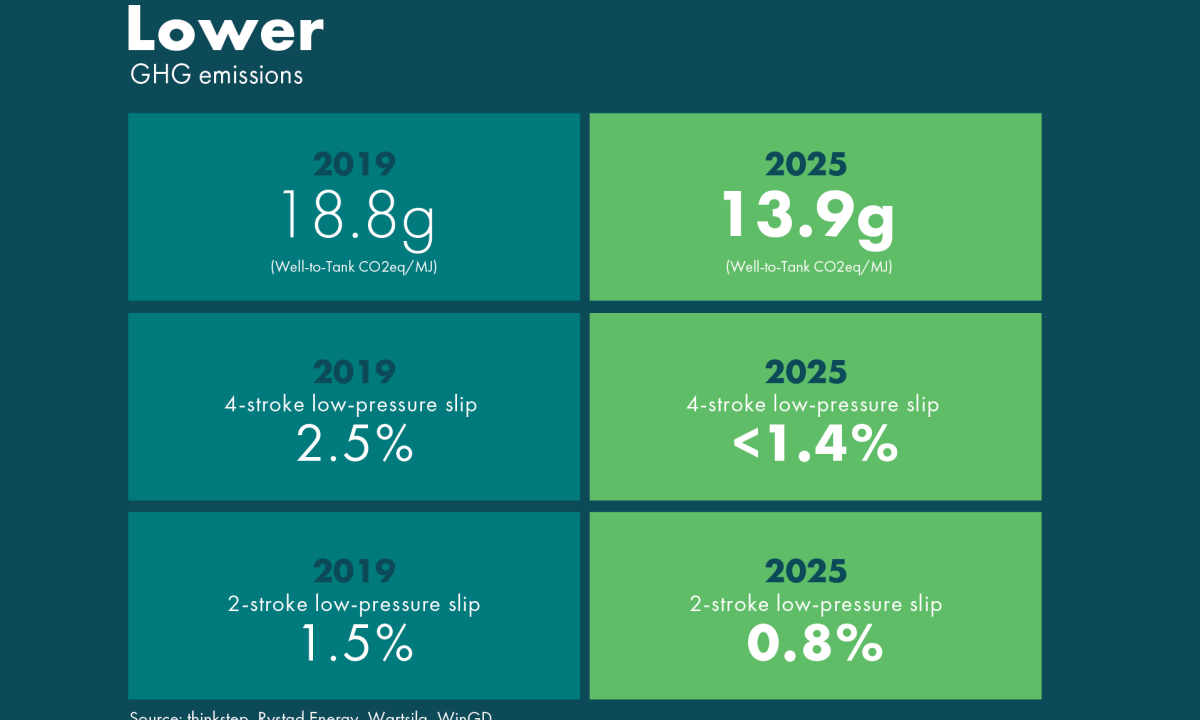

Fossil LNG is not without its challenges, however. While it burns cleaner than distillate fuels – burning LNG in a modern combustion engine immediately reduces GHG emissions by 6-23% compared to the diesel engine – it also results in small levels of methane leakage during production and combustion.

Bio-LNG is, morally-speaking, the correct route to take, since it works on the principle of Waste-To-Energy using manure, municipality waste and waste waters and many other types of waste. A lot of R&D has gone into testing carbon-neutral biofuels. However, the critical aspects to consider when selecting a fuel for a new vessel are availability and energy density. Biomass-based fuels are only sustainable when local availability of feedstock is plentiful and guaranteed. Today, the supply chain is unevenly developed, but the latest studies suggest that a sustainable energy supply could be in place by 2030. It is estimated that biomass-based fuels extracted from forestry products and residues, agricultural residues, and crops grown for energy on surplus land could yield enough volume to supply the whole marine industry and most heavy road transportation with bio-LNG, assuming all vessels would be converted to LNG. Depending of the source of biomass (eg manure), the total CO2 emissions of a fuel value chain can even become negative.

Today’s mechanisms used in the maritime industry to calculate total emissions do not consider the full value chain. However, the climate alignment and green risks are reflected in the credit rating and responsible ship financing already.

Potential fuels of the future

On paper, hydrogen fuel cells present an exciting proposition because they convert clean hydrogen into electrical energy and steam without the need for an emitting combustion process. However, the cost of producing fuel cells and the lack of a green hydrogen refuelling network means that this technology is not yet scalable, especially for huge ocean-going ships.

Large-scale hydrogen production based on electrolysis demands large amounts of energy and has low total efficiency. This is perhaps one of the biggest challenges for hydrogen as a fuel itself, and for any other synthetic fuels based on hydrogen. Due to the challenges with fuel cells, other sources for hydrogen recently have gained attention, such as side streams from the chemical industry, or gasification of biomass or recovered waste, ie. plastics. This has kickstarted research into circular economy-thinking through which we might well see future business and economic growth.

Even if renewable energy becomes available with even lower costs, however, the production of hydrogen is not the biggest challenge to its use as a fuel. Another significant challenge is the storage of hydrogen as fuel. To achieve higher energy densities hydrogen has to be stored as either compressed gas or as liquid. As a gas, it typically requires high-pressure tanks, while storage as a liquid requires cryogenic temperatures because the boiling point of hydrogen at one atmosphere is -253 degrees Celsius, which adds to the complexity.

This challenge makes synthetic fuels that can be considered hydrogen carriers more attractive. Hydrogen can be bound to CO2 or N2 in the form of CH4 (methane), CH3OH (methanol) or NH3 (ammonia), which makes the transportation, storage and the conversion of the energy much easier. But these options also have challenges. Green ammonia or hydrogen will not be viable solutions for near term, nor for all applications even at a mid to long term horizon. Methanol may become commercially viable to some extent, and fuel cells will be applicable for certain segments in shipping with lower power demand or short distances as well as for road transportation. Large scale adoption of the hydrogen fuel cell as the primary energy source is unlikely for many years to come and cannot be consider a solution for shipowners wanting to do a change today.

GHG emissions are global and cumulative emissions having an overall budget linked to the agreed temperature increase. Therefore the decarbonisation challenge only gets tougher the later we take steps to address it, and thus waiting for options is not an option. The maritime industry must act now and implement future-proof technologies and bridging fuels that are available today, but will also ensure required fuel flexibility for the future.

A new ecosystem

At Wärtsilä, we’re taking a big picture approach to tackling the targets and improving sustainability in general. We are working towards a Smart Marine Ecosystem that involves all aspects of the maritime economy. In a Smart Marine Ecosystem, ships are technologically smart, using cloud-based software and digitalisation to minimise the use of energy and reducing fuel consumption. These vessels travel between smart ports that dynamically manage traffic so that ships no longer need to queue to dock. A connected ecosystem will see greater cooperation between shippers so that vessels sail with full cargo loads, thus enabling more cargo to flow using the optimal number of vessels. Improving efficiency across the value chain will certainly reduce waste in day-to-day operations.

But the biggest success in reducing emissions will involve the fuel mix used by engines. The fuel-flexible combustion engine presents itself as a future-proof technology that will enable the industry to meet future targets as and when alternative and renewable fuels become available. What we really need to see is fiscal policies, regulatory frameworks and long-term contracts that encourage expanding capacity investments for biogas and synthetic fuels.

We have the technology; the time to act is now.