8th August 2024

FACT FROM FICTION: METHANE SLIP

It’s human nature to have an opinion. And everyone is entitled to one. What’s potentially damaging is when emotive opinions with limited substance are heralded as fact. Waiting for theoretically perfect solutions risks delaying real progress that can be made today. Currently, there is much false and inaccurate information proliferating about LNG as a marine fuel.

Let’s clarify some common questions regarding LNG and the pathway forward and provide facts that are based in science and engineering.

When will the methane slip issue be solved?

With continued collaborative efforts across the LNG value chain, there is increasing evidence that methane slip will be eliminated for all engine technologies within this decade.

How will the methane slip issue be solved?

Today, 2-stroke, diesel cycle engines account for approximately 75% of the LNG-fuelled vessel order book. These engine technologies have effectively already eliminated slip. For low-pressure engine technologies where methane slip remains an issue, manufacturers have already cut the levels of slip from low pressure 4-stroke engines by more than 85%. It is worth noting that methane slip has been eradicated for the similar LNG dual fuel engine technologies used in the heavy-duty vehicle sector. The science and technology exist and this, combined with innovative engineering in the maritime sector, will soon solve the problem.

By how much can LNG cut GHG emissions, including methane?

According to the 2nd Lifecycle GHG Emission Study on the use of LNG as a Marine Fuel commissioned by SEA-LNG and SGMF and conducted independently by Sphera, LNG can cut GHG emissions by up to 23% including methane emissions across its entire lifecycle, Well-to-Wake, when compared to fuel oil. While significant, this is only the first step in the LNG pathway.

What can we use instead of LNG to avoid methane slip?

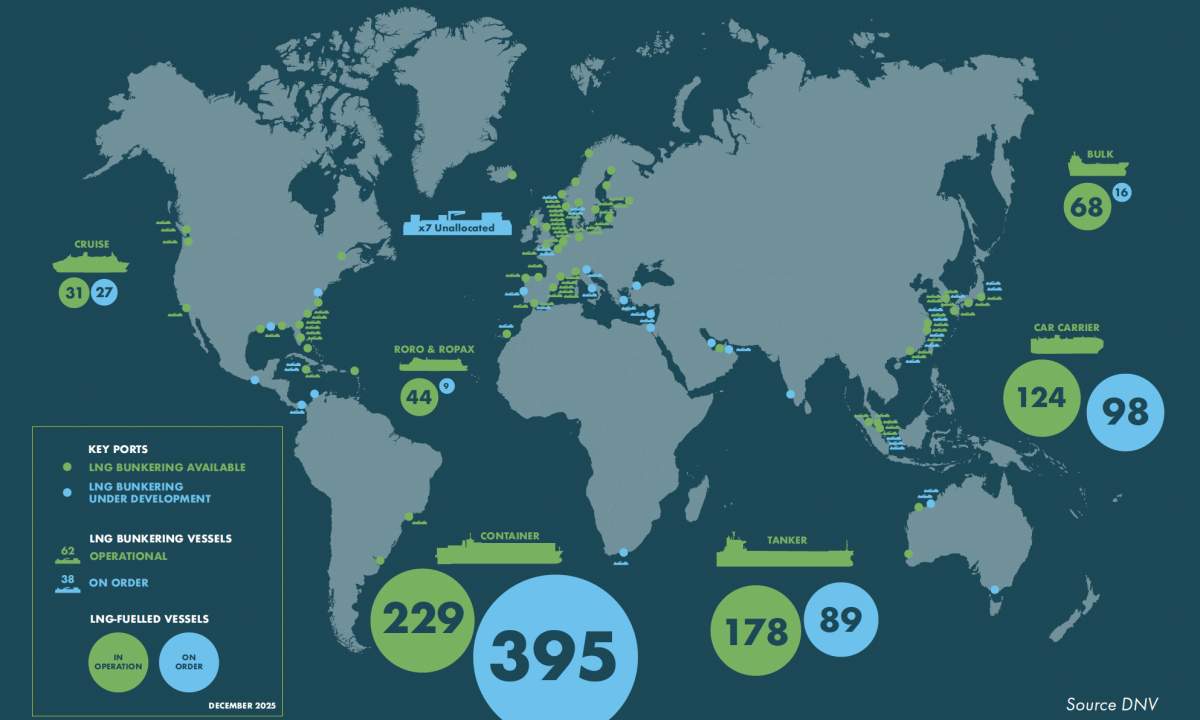

Uptake of the LNG pathway is accelerating. Clarksons’ data shows that 109 LNG-capable vessels were ordered in 2024 to June, which over the course of the year is likely to align with the 221 LNG-fuelled newbuildings booked in 2023. LNG continues to gain widespread recognition as the only current practical and realistic alternative fuel pathway. Other alternative fuels are simply not scalable or affordable in the necessary timeframes to meet the IMO’s emissions reduction targets.

Why are shipowners increasingly opting for LNG-fuelled vessels?

There is universal agreement that the science is understood, and we have the necessary tools and technology to abate methane emissions. The industry is now working on the final elements of the engineering that will solve the issue. This, in combination with the option to transition to net zero emissions through safe bio-methane and e-methane, provides ship owners and operators with the confidence that vessels ordered today are future-proofed for the next 25 – 30 years. This cannot be said for any other alternative fuel right now.

What about local air pollution?

Local air quality is still a major global issue. Air pollution is responsible for 6.7 million premature deaths every year, according to the World Health Organization. Pollutants that have the most concern for public health include particulate matter (PM), carbon monoxide (CO), ozone (O3), nitrogen dioxide (NO2) and sulphur dioxide (SO2). LNG emits virtually no sulphur oxides (SOx) and virtually no particulate matter (PM). Compared to existing heavy marine fuel oils, LNG can, depending on the technology used, emit up to 95% fewer nitrogen oxide (NOx) emissions. (SO2 and NO2 are the predominant forms of SOx and NOx respectively.)

Should we observe the 20-year global warming potential or 100-year global warming potential?

The industry uses the 100-year Global Warming Potential (GWP) for greenhouse gases which is the recommendation from the United Nations Framework Convention on Climate Change (UNFCCC). As there is increasing evidence that methane slip will be eliminated for all engine technologies within this decade, the choice of GWP20 over GWP100 will have minimal impact.

Can you provide some examples of how methane slip is being reduced?

As part of the EU-funded GREEN RAY project, Wärtsilä has piloted technologies on the AURORA BOTNIA RoPax ferry resulting in further methane slip reductions of up to 56% in one of its most popular, and already emission-efficient, dual fuel low-pressure four-stroke engines.

ROTOBOOST, a global hydrogen technology company, has developed a unique pre-combustion carbon removal system based on Thermo-Catalytic Decomposition (TCD). The technology can be equipped onboard vessels, cracking the methane molecule into hydrogen and solid carbon. The hydrogen is being mixed into the methane fuel feed flow to the engines, directly contributing to lower methane and carbon dioxide emissions, while the valuable solid carbon is captured on board and off-loaded at the next port call to find its way in a large variety of industrial products.

MAMII has begun a process of piloting exhaust stack methane abatement technologies, including from Green Instruments and Everimpact. It is also working on a methane measurement, certification and validation protocol for regulators.

In September 2023, Maran Gas highlighted the installation of methane measuring technology and Daphne Technology’s after-treatment abatement system, SlipPure, integrated on a dual-fuel LNG carrier. Shell was also involved in the project.

In November 2023, MAN Energy Solutions announced that it is launching the IMOKAT II project to develop an after-treatment technology to reduce methane slip from its four-stroke engines.

Where can I find more information about methane slip?

For more information, see the methane slip fact sheet on our website.